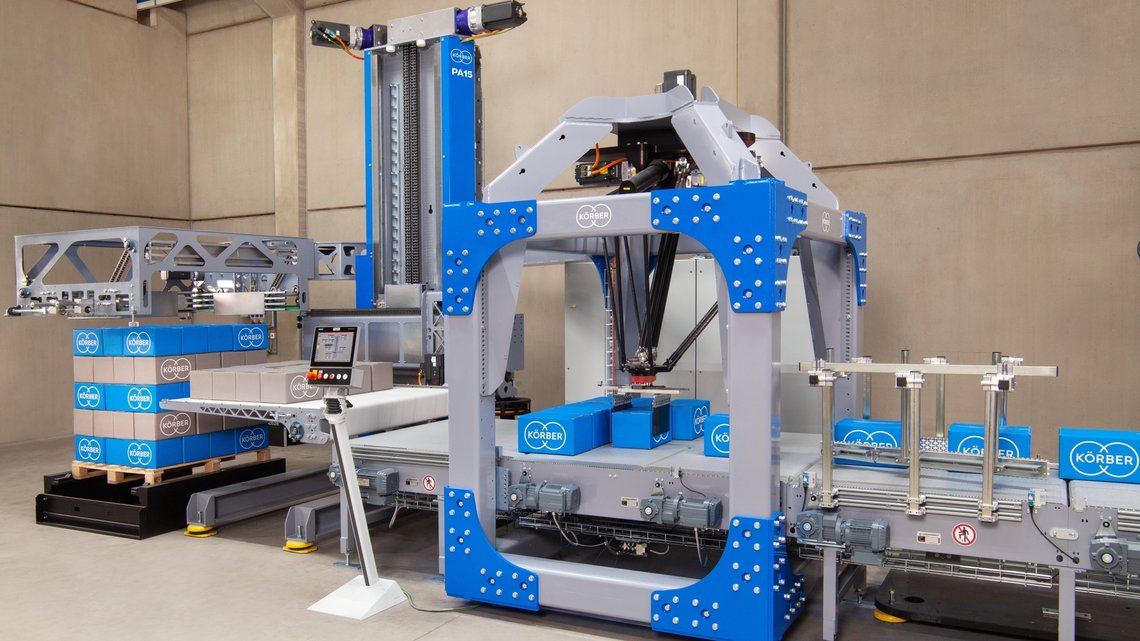

Palletizing and Conveying Solutions

Körber's palletizing and conveying solutions optimize manufacturing production lines by conveying and packing goods onto pallets for transfer and delivery. Automating this process results in faster cycle times and higher levels of precision, increasing efficiency and reducing costs while improving worker conditions and safety.

Palletizing challenges in modern manufacturing operations

The demands of modern manufacturing and production make it increasingly difficult for companies to grow, scale, and accelerate their operations efficiently and cost-effectively.

One solution to these challenges is palletizing, the process of automatically stacking products in various packaging options onto pallets for more efficient storage and transportation. By implementing palletizing systems, companies can streamline operations, manage labor requirements, and increase worker safety. With the right palletizing equipment and expertise, companies can realize improvements in productivity and profitability.

Innovative Conveying and Palletizing Solutions

Within the Körber Ecosystem, the competence area Manufacturing Logistics specializes in palletizing and conveying systems for the tissue, bakery, and consumer goods industries - setting new industry standards for quality, reliability, process stability, and longevity. Our end-to-end solutions seamlessly integrate mechanics, hardware, and software to provide complete automated palletizing and conveying solutions. This tight integration ensures optimal performance of all components. In addition, our proprietary engineering solutions have the versatility to convey and palletize virtually any product, and are flexible enough to adapt to different manufacturing environments.

Lightweight Conveying Equipment

Precision product handling and transportation are essential to optimizing in-plant material flow. Offering a choice of drive and tension units to match belt length and load weight, our Lightweight Belt Conveyors are ideal for transporting light to moderately heavy products. Our Roller Conveyors are designed for light as well as heavy products, and can be adapted to a variety of space conditions. These units are impervious to dust, making them well suited to dusty environments.

Pallet Conveyor Equipment

Whether stacking or separating empty and full pallets, or moving pallets between different transport levels, we have a pallet conveyor to meet the task. Our range starts with the more economical driveless models, all the way up to driven roller or chain conveyors, complete with reversible transport direction and high pulling power. We also offer transfer units and turntables to connect transport lines and change pallet direction, as well as automatic pallet shuttle cars.

Tissue solutions

Tissue manufactures is facing significant pressures in terms of pulp price volatility and competition in global markets, and are looking for OEE improvement, product differentiation, and sustainable solutions. We offer the industry most comprehensive portfolio of tissue technology to support tissue manufacturers across the entire value chain - from roll to fold, from converting to packaging. This includes advanced digital services and engraving technologies as well as unique value chain concepts.

Our Palletizing Benefits

- Deep expertise: Our palletizing and conveying expertise are coupled with a deep understanding of software and systems integration for all end of line applications.

- Flexible options: No off-the-peg solution, systems are custom built to fit material flow environment and each customer’s individual requirements.

Innovative Palletizing and Conveying Systems

In a highly competitive business environment, precision palletizing and conveying is critical to increasing production, reducing costs, and optimizing material flow. The key to supporting this is an automated palletizing solution that is seamlessly integrated into the in-plant logistics.

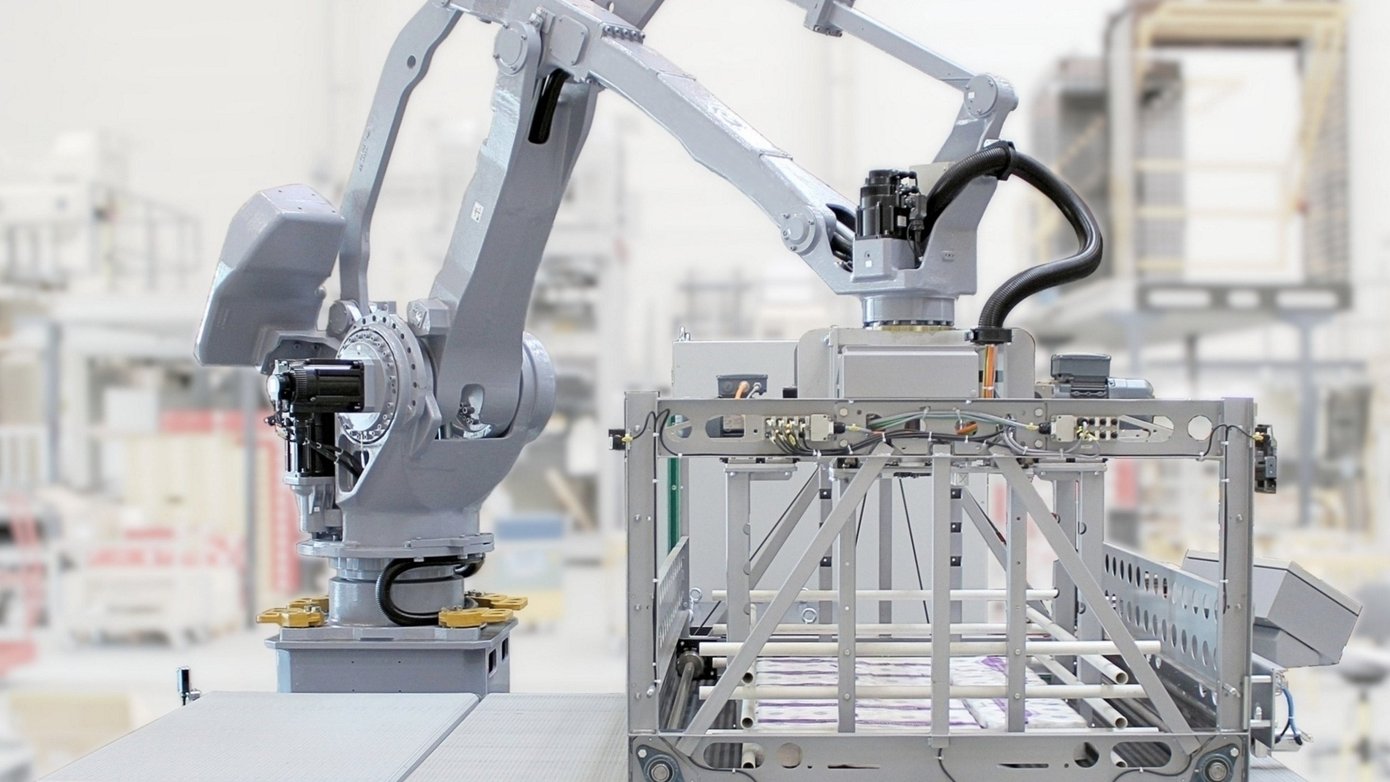

We offer a wide range of palletizing systems to meet this need, including both the software and the layer and robotic palletizing hardware. These systems are constantly improved to meet both customer needs and the ever-increasing demands of the market.

Solutions are first developed by a team of designers, technicians and engineers. These are then implemented by production and assembly teams to ensure timely and customer-focused project delivery.

A key component of our solutions is our expert advice. Our qualified sales engineers and project managers are committed to finding the right solutions to meet our customers' needs, no matter how complex they may be.

The benefits of our palletizing solutions

- End-to-end solution: We deliver complete automated palletizing solutions, which means the mechanics, hardware and software are all closely attuned to each other.

- Tailored delivery: Our palletizer solutions are designed with the customer in mind, accounting for the unique requirements of their market, their business, and their objectives.

The Körber difference

We provide end-to-end solutions, complete with the infrastructure and portfolio of products, tailored to each customer’s requirements. As a global technology business, we have the scope, R&D opportunities, and manufacturing capacity to develop the next generation of palletizing equipment and auxiliary components, giving us an unrivaled position within the consumer goods logistics industry.

From conceptualization and design to development and production, our expert teams provide practical, automated palletizing solutions to resolve complex logistics tasks to meet our customers’ operational needs. This expertise, combined with our end-to-end hardware, software, and system integration, is the foundation for optimal material flow, streamlined processes and increased productivity.