Petrochemical

Compared to many other sectors, supply chain management in the petrochemical industry presents some unique challenges, which demand highly specialized logistics solutions. The dynamics in the industry make it difficult to forecast and time logistics for sourcing, delivery and transportation – particularly with the more recent development of unconventional oil sources such as shale.

Price volatility of feedstock and derivatives requires petrochemical sites to be flexible in their production schedules. Added to this, long distances and multiple transportation modes can cause delays along the supply chain.

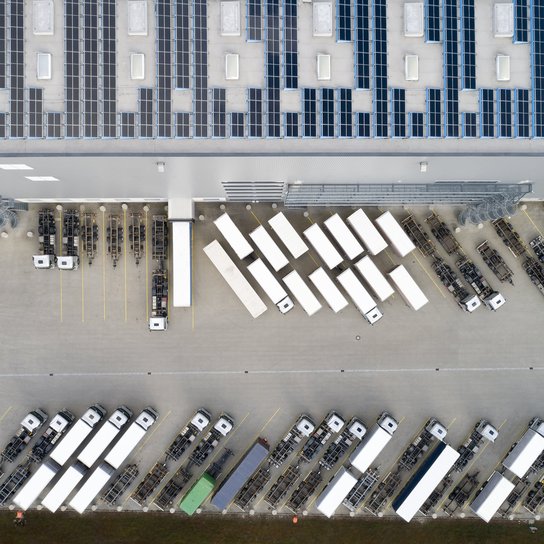

The production process in petrochemical plants is continuous. To make products derived from crude oil – e.g. plastics, soaps, fertilizers and paints – other raw materials need to be sourced and their deliveries timed to ensure ongoing availability for manufacturing. Once produced, finished goods need to be removed continuously. Yard operations are complex and require highly specialized automation systems to move raw materials onto the site, and finished goods onto outbound transport.

These bulk products are packaged in multiple formats suitable for different modes of transportation, and are often flammable or explosive, so require special handling.

Industry challenges

The complexity of petrochemical supply chain management is rooted in the overarching requirement to ensure continued operation of the plants and removal of finished goods. This makes it essential to integrate and synchronize processes, from procurement and delivery timings of raw materials, through multiple product manufacturing, to the removal and delivery of final products. Supply and demand dynamics mean that both raw materials and finished products need to be sourced and transported at exactly the right time.

This involves the simultaneous planning, scheduling and execution of supply, production, packaging and disposal processes, all while staying receptive to operational and market changes.

As many of the goods are hazardous, both safety and track-and-trace capabilities are paramount.

In addition, the qualification levels of the workforce range widely. Workers in the yard and in production often need detailed instructions for their specific tasks and the hazardous conditions they work in.

The Körber difference

We have a 25-year track record delivering a range of petrochemical supply chain management solutions, including site logistics systems as well as design and simulation solutions. These solutions address the complexities of raw material sourcing, manufacturing, transportation, and delivery; effectively enabling you to manage your own supply chain processes, optimize efficiency and maximize profitability.

Key capabilities include:

- Inbound and outbound transportation management by truck, rail or ship

- Highly specialized container management on the yard and in the depots

- Control of supply, production and material flow with complete inventory transparency

- Integrated planning and scheduling of production, packing and shipping processes

- Forecasting to enable a timely reaction to sudden changes in the production schedule

- Seamless integration of all common logistics systems (including production planning systems/ERPs and automation equipment)

- Batch, lot and grade traceability from production to the end customer

- Comprehensive dangerous goods management

- Planning and control of shipping operations, significantly reducing marine terminal demurrage costs and delay times

- Support for task instruction via mobile terminals to guide workers through yard and transport management tasks

Sophisticated yard management functionality provides real-time control of reach stackers, forklifts, cranes and switchers. Drop and swap management for containers, goods wagons, and trains enables the constant supply of materials for production, and continuous removal of finished goods.

Where you require, we can design an infrastructure strategy for multimodal distribution networks aimed at increasing efficiency and reducing your cost-to-serve.