Layer picking challenges

Organizations face a range of challenges when it comes to layer picking:

- Increasing cost and complexity for manual layer picking as volume grows

- Lack of space in existing facilities due to growing volumes

- Limited budget for investment in automation

By using warehouse space more efficiently, reducing the need for manual labor, improving layer picking accuracy and speed, and cutting product damage, our automated Layer Picker systems resolve many of the issues associated with complex layer picking.

This fully integrated solution is designed to reduce operational costs, while optimizing efficiency, productivity and available space in your warehouse or distribution center.

Revolutionizing your warehouse processes

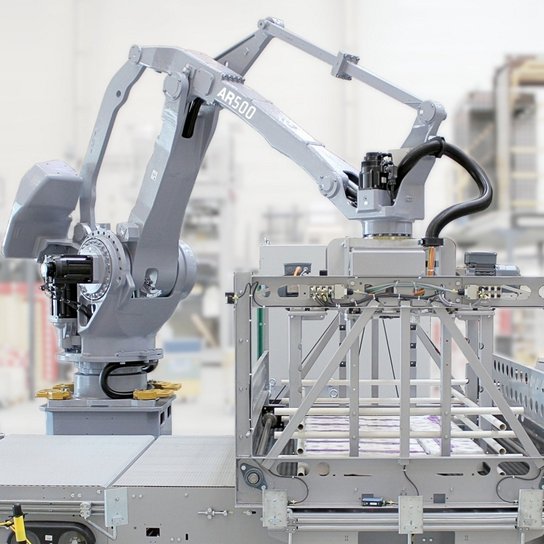

Our fully-integrated Layer Picker Gantry systems provide automated de-palletizing and pallet-to-pallet picking. This unique, automated, flexible solution can be scaled up to 10,000 picks per day.

Our solution can automatically build rainbow pallets with different layers, while providing automated storage of pallets and improving the working environment in warehouses and distribution centers.

It provides unmatched performance for your warehouse.

- The most versatile solution on the market, with unrivaled technology and unique suction and clamping layer picking method.

- More than 600 Layer Picker installations globally.

- Industry standard for de-palletizing and pallet-to-pallet picking.

- Picks both single or multiple layers and layers with voids.

- Operating in temperature ranges from −28°C to +40°C (−18°F to +140°F).

Layer picker in use

Heinz National Distribution Centre (UK)

Körber’s Layer Picker provided Heinz with an improved picking profile compared to the previous technology.

Designed to create “sandwich/rainbow” pallets of mixed products to customer specifications, the solution offers a throughput of up to 180 layers per hour and is designed to operate 24/7 in peak periods.