Layer Wave

Through a unique combination of conveying and layer gripping, the Layer Wave can pick complete product layers from a conveyor line and place them gently on a pallet, regardless of product or layer pattern.

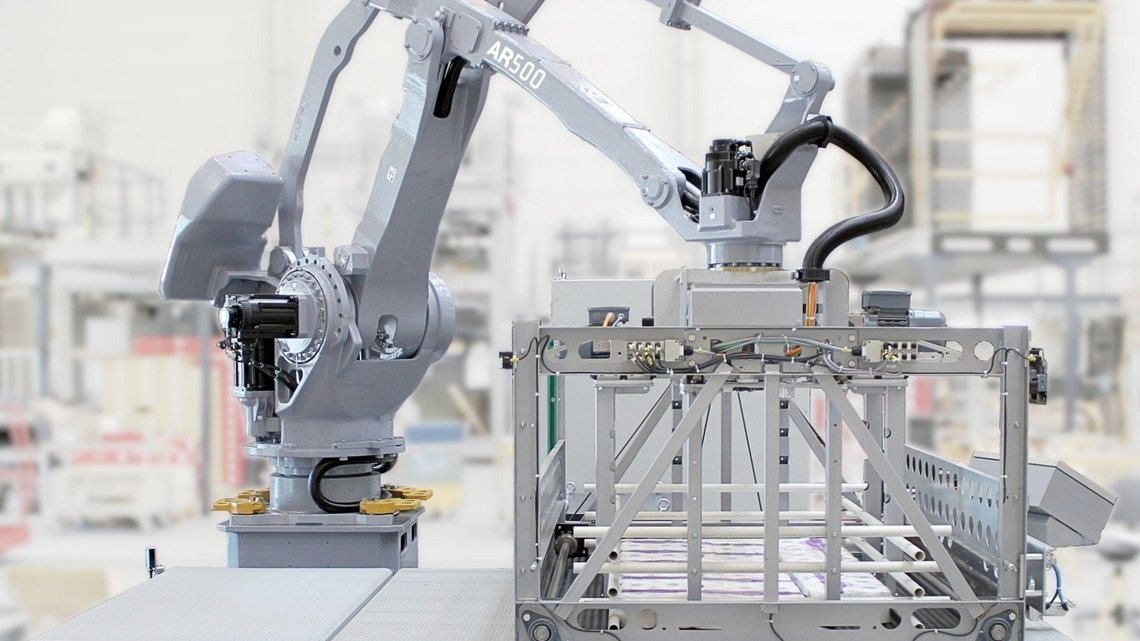

Unlike conventional systems using fork or clamp grippers, its compact design provides space savings of up to 40%. Combining it with the Robot Palletizer AR500 provides a complete, accurate, coordinated flow solution.

By adding a gripper system to one of our automated palletizing robots, you can ensure safe and damage-free handling, thanks to the product protective lifting function and 4-sided product compression.

Interleaf inserters and line diverters can be introduced to support continuous distribution of up to three lines of the infeed, across a broad range of products.