Multiple and constantly changing distribution channels present a major challenge

Order picking is the most complex and dynamic of all logistical workflows:

- Retailers struggle to support multiple B2B, B2C and online distribution channels simultaneously.

- There is a huge time factor in manual order picking for a growing assortment of goods for different omnichannels.

- Warehouses and distribution centers face increasing problems with labor costs and scarcity.

Order picking solutions

Our customers experience growing complexity through “omnichannel” distribution channels – from traditional retail supply, to one-off, next-day and same-day e-commerce orders.

Körber’s order picking and distribution solutions are firmly analysis-based: who your customers are, what you are distributing, at what frequency and through which channels.

We look at your floor space, how you store your products, your distribution channels, order lead times, assortments and quantities. We analyze your entire business scenario relevant to the most competitive supply chain, considering the past, present and future.

The detailed data we gather determines the most efficient workflows, software and automated technologies you need to fulfill your customer needs across all distribution channels.

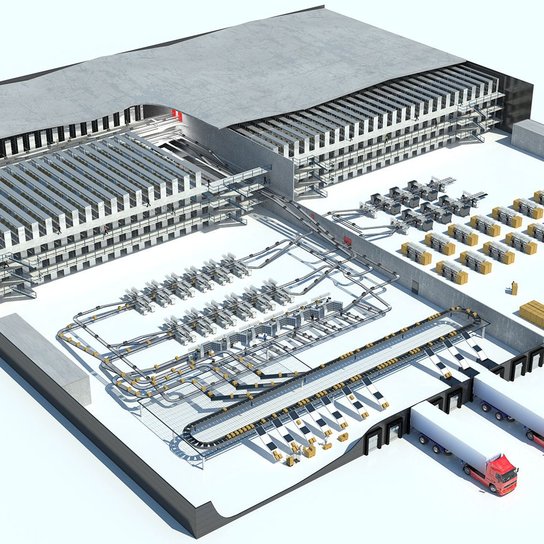

We design highly optimized person-to-goods solutions, either with handheld terminals or voice-directed. If needed, we can integrate autonomous mobile robots to support these processes. Or we can design an advanced automated goods-to-person solution, applying a wide range of technologies from mobile robots to shuttle systems. In all cases, Körber has the experience and processes to design, deliver and support these solutions.

Key benefits

Technology agnostic

We don’t stick to any single technology. We deploy the technologies that work best to increase your process innovation and reduce your business complexity.

Practical thinking

By understanding the business processes and material flows you require to optimize your competitiveness, we shape the optimal supply chain solution for you.