Consumer expectations have increased sharply: high quality, freshness and variety across categories, independent of the seasons. And that is just the beginning. The growing number of small and single-person households drives the demand for small and individual unit sizes, while ingredient-limited foods and environmentally conscious products with sustainable sourcing and packaging further increase product variety. This is all set against a backdrop of constant pressure to reduce costs in order to remain competitive.

Some food and beverage companies choose to manage their own supply chains, while others delegate certain elements to third parties. Whatever the approach, they must ensure high operational performance and regulatory compliance to protect their businesses and ensure a safe food and beverage supply chain.

Industry challenges

The food and beverage industry has to be highly agile to proactively respond to changes in demand due to seasonality and promotions, as well as to disruptive forces such as new brand launches and mergers. These factors can be mitigated with effective supply chain management.

Advanced inventory management is a key requirement when facing a growing variety of products, packaging sizes and types – effectively addressing the resulting SKU proliferation is essential for success.

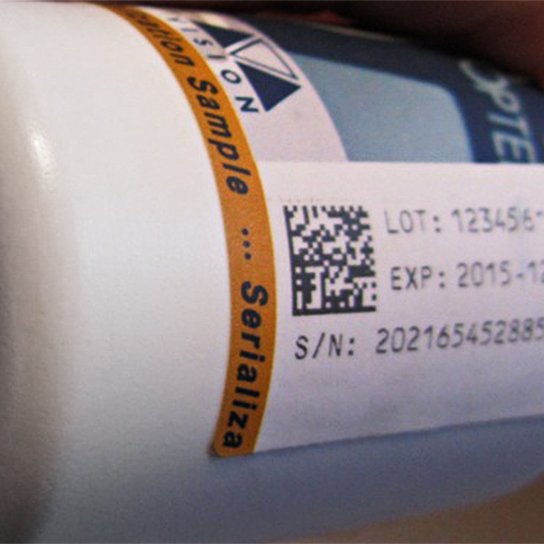

Complete traceability of ingredients and finished products is also crucial, as it allows companies to react quickly and decisively in the event of a recall, while supporting compliance and ensuring a safe food supply.

Additional challenges include:

- Inventory management according to expiration dates, as many retailers only accept items with set minimum expiration periods

- The risk of food contamination

- Reduction of food spoilage to help control costs

- Compliance with rapidly evolving regulations and standards

- Retailers who need to stock larger numbers of SKUs, but with smaller order volumes

New cross-sector challenges for food distributors are also emerging, including rising consumer demand for omnichannel commerce with highly flexible delivery options. These often require innovative supply chain solutions, such as dark stores or click and collect.

The Körber difference

We understand the challenges of the food and beverage supply chain, and are uniquely placed to solve them. Our comprehensive and adaptable software solutions enable you to remain competitive in this challenging market.

To help you evolve and grow, our software solutions provide industry-specific inventory management capabilities, such as configurable expiration date management, including first-expired-first-out (FEFO) date rotation to accelerate inventory turnover. Capabilities like end-to-end product and batch traceability, built-in recall management, and integrated temperature zone management for storage and transportation, help ensure food safety. Seasonality of products also impacts transportation planning, and can be accommodated with features like advance transport scheduling and frame route management, as provided by our transportation management system (TMS).

To facilitate handling of products in the warehouse, we can integrate industry-specific automation equipment, including specialized picking, and packaging systems which can assemble mixed pallets. Our industry-leading warehouse control system will provide a single, vendor-agnostic point of control for your costly material handling equipment and optimize its performance.

Also, our warehouse management solution can be seamlessly integrated with our advanced TMS and yard management system, to optimize operations across your entire food and beverage supply chain.