Layer picking challenges

Warehouses and distribution centers face a range of challenges when it comes to layer picking:

- The more items that need to be picked, the greater the operational demands

- Fast-changing SKU profiles leading to complex layer and case picking

- Space requirements due to increased picking activities

- Recruiting manual labor for picking

- Providing ergonomic working practices

- Increasing cost of damaged products

- Picking errors in the manual picking process

Automated layer picking for increased efficiency

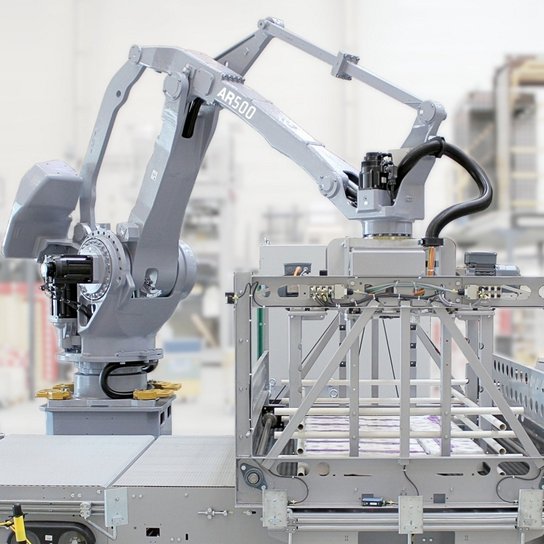

Using the unique, patented combination of suction and clamping techniques, our innovative Layer Picker can pick up to 98% of all product types in food retail. With more than 700 installed worldwide, Körber Layer Pickers are helping customers meet the growing challenges of picking goods today, whether that is in a food retail distribution center, a 3PL operator’s premises or at an FMCG warehouse.

The Körber Layer Picker is designed to eliminate manual picking, increase warehouse efficiency and drive down labor costs. It meets the demands of highly dynamic industries such as the food retail sector, where the requirements for efficient and reliable logistics processes are constantly increasing. Complex order structures, high volume throughput and increasing demand for faster delivery require flexible handling of a high variety of articles.

When it comes to deployment, it can be installed in freezer warehouses, delivering the same level of picking automation as in the ambient environment. It contributes significantly to increased efficiency and lowered costs in freezer warehouses, compared to manual labor.

It can be integrated into many types of warehouse management systems (WMS) and warehouse control systems (WCS). It can also be delivered as a standalone solution, complete with its own WCS to facilitate order execution, pallet replenishment and full traceability through the WMS.

Automating the entire process: from pallet to tray

More often than not, products are distributed in single cases rather than in full pallet and full layer quantities, especially in the retail industry. That’s why we’ve designed our Layer Picker and downstream equipment to fully automate the delivery of high volumes of products, from pallets to single cases, onto a system tray.

With our Layer Picker Robot, Hoist and Gantry, we have a solution for almost every application. We can also tailor our modular solutions to your business requirements, adding downstream equipment components, such as the Stripper Plate (to remove slip sheets between layers), Descrambler (to split layers into single cases), Box Turner (to orientate cases), and Tray Loader (to load cases onto system trays).

Our range of turnkey solutions and in-depth knowledge means we can help you manage the entire process to deliver single cases on system trays, using the Layer Picker with complete downstream equipment.