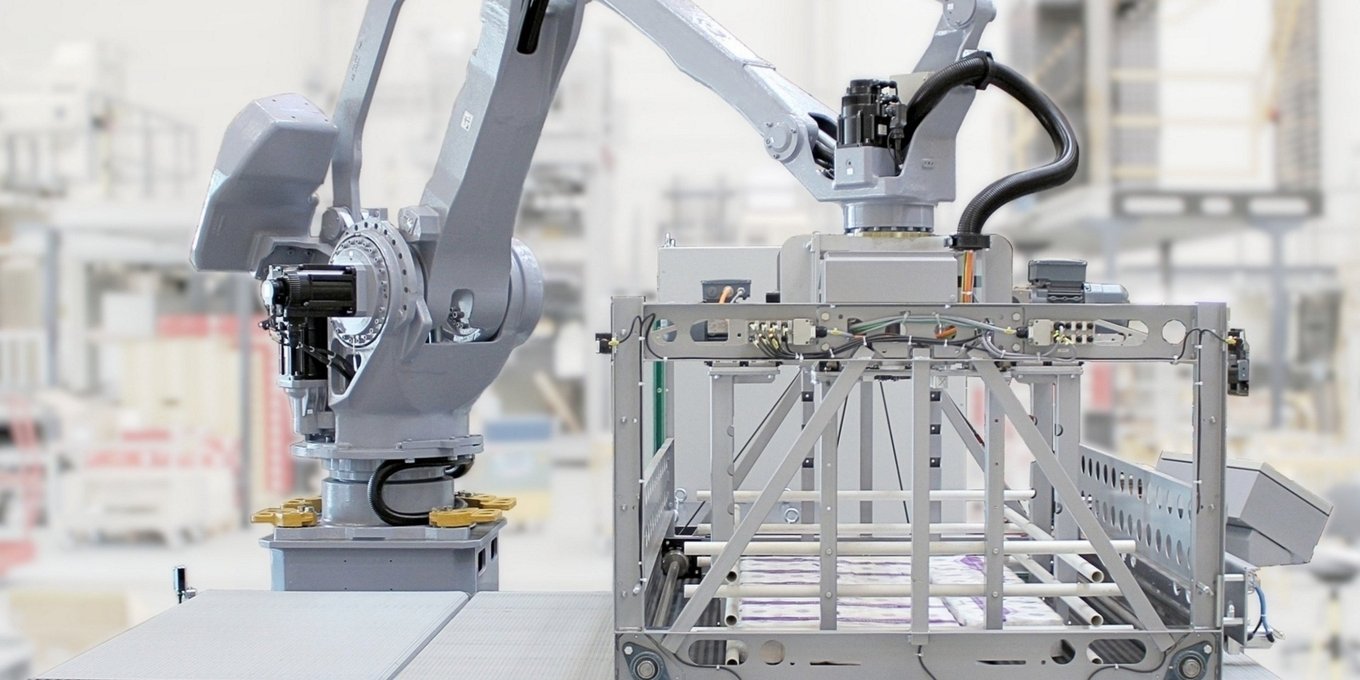

Palletizing Equipment

Our range of high-quality, high-performance palletizing equipment is designed to operate at the highest product volumes, even within limited building dimensions. Capable of handling everything from heavy pallet crates to individual sensitive products, the equipment is both versatile and efficient.

Industrial pallet challenges

Meeting the demands of today’s multi-channel, multi-fulfillment market creates several palletizing challenges, particularly for small-to-medium sized production plants:

- High-volume, mixed product throughput, including both pallet crates and delicate items

- Limited plant floor and ceiling space

- Costly and time-consuming equipment installation

- Limited equipment operator availability and training time

Palletizer product range

We offer a range of equipment from robot palletizers and layer palletizers to gantry robots and grippers, to suit even the most limited of building spaces. The equipment is robust enough for the heaviest of throughputs (up to 40 products per minute), but delicate and precise enough to handle sensitive items. Pallet roller conveyors with flanged alignment rollers ensure optimal positioning.

To simplify user operation, our robot palletizers use the open controls concept, including visualization with either Siemens or Rockwell technology.

Designed for limited spaces and multiple product formats, the case stacker KST05 is the first choice for fully automated stacking and palletizing.

The Layer Palletizer PA14 is particularly suited for palletizing pre-stacked containers, with an upstream shuttle system that supports handling of mixed product stacks and pallet loads.

By adding a gripper system to one of our automated palletizing robots, you can ensure safe and damage-free handling, thanks to the product protective lifting function and 4-sided product compression.

Interleaf inserters and line diverters can be introduced to support continuous distribution of up to three lines of the infeed, across a broad range of products.

Key benefits

Immediate accessibility

Easy operation, low worker intervention, and short implementation times, means that customers can rapidly realize the productivity benefits of our automatic palletizers.

The Körber difference

We provide a suite of high-performance robot and layer palletizing equipment, designed to handle the demands of today’s high-volume, multi-product fulfilment environment. Whatever the production plant dimensions and whatever the product, we have an easy-to-use, cost-effective palletizing equipment to match, enabling even the smallest of operations to enhance their productivity.