This also means that production lots become smaller. To maintain overall volumes, larger numbers of orders need to be fulfilled, while reducing costs.

The resulting complexity drives a need for increased efficiency across the manufacturing supply chain. This has necessitated the adoption of new “lean” manufacturing strategies such as Build-to-Stock (BTS) and Build-to-Order (BTO).

The manufacturing supply chain depends on these key factors to ensure continual, accurate production:

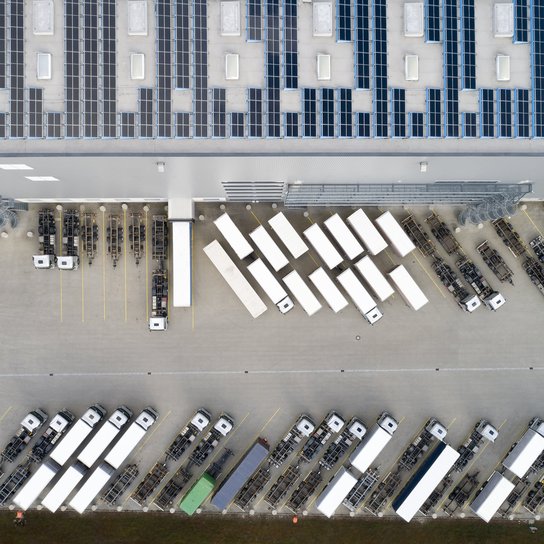

- Reliable goods flow

- Constant material availability

- Efficient distribution processes of finished products

While there is a constant drive for efficiency in the manufacturing supply chain, it is often exposed to external influences which could easily disrupt productivity and customer satisfaction. Common examples include strikes, supply shortages, and even road closures. A mistake, such as the supply of the wrong raw materials, can be enough to lose customers or cause serious damage to manufacturing equipment.

These influences need to be mitigated while controlling operating cost and ensuring continual availability of materials.

Industry challenges

Manufacturing supply chain solutions have to support synchronized processes for manufacturing and logistics.

Efficient planning of production supply and removal processes is a core requirement for supply chain solutions, with the goal of minimizing production time, even for highly individualized products. To this end, securing a constant supply of raw materials, and effective labor resource planning, ensures smooth production processes and extends the duration of stock coverage.

Manufacturing supply chain solutions also need to ensure:

- Tight integration of production planning with supply chain solutions to ensure timely availability of production materials and removal of finished goods

- Integration with highly specialized material handling equipment, and customization of automation processes toaccommodate the wide variety of finished goods

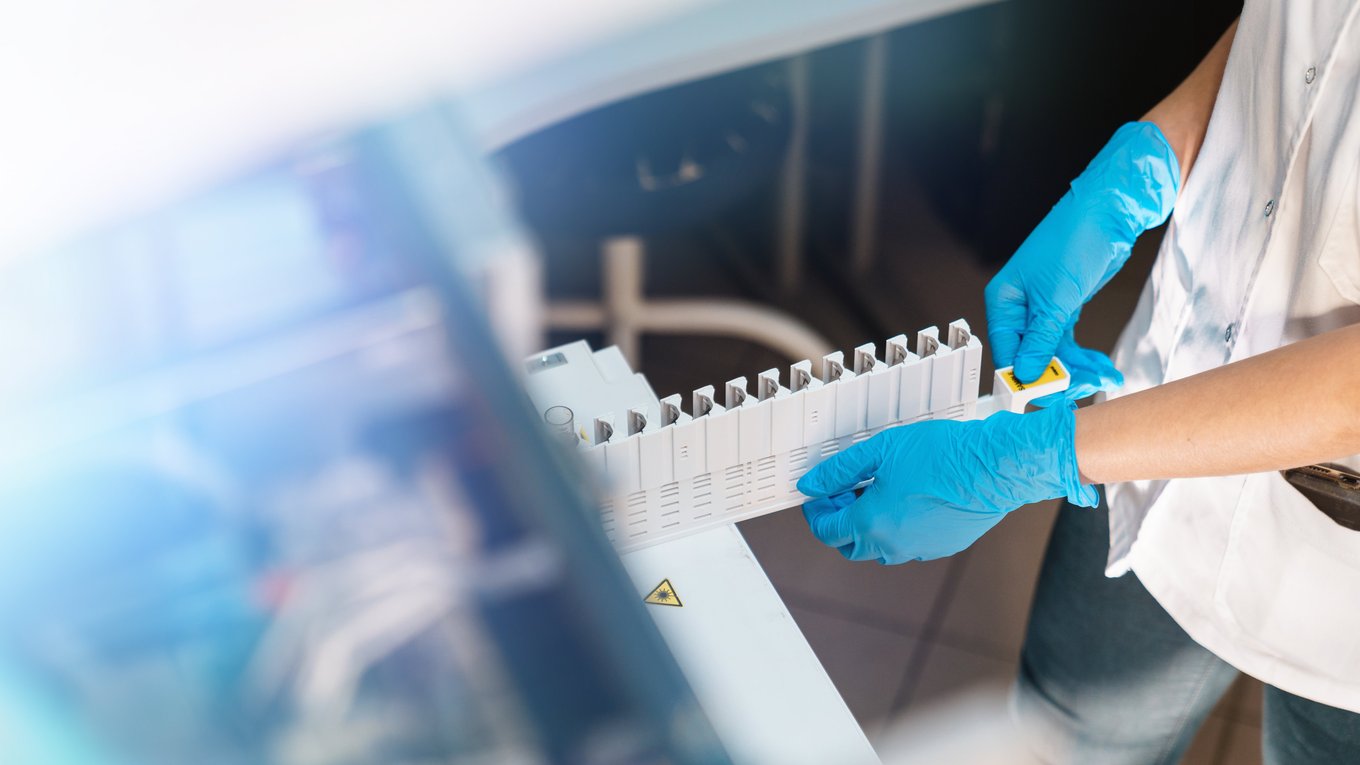

- Support for the quality control processes and traceability required in this highly regulated sector

The Körber difference

We understand the overarching need for efficiency and cost control in this sector, to keep manufacturers agile and profitable.

The growing need to embrace BTS and BTO manufacturing strategies creates specific requirements for manufacturing supply chain solutions. Our solutions address these with support for demand-driven material flow processes (just in time/just in sequence) to ensure accurate production supply. In addition, they can be customized and extended with incremental functionality to support specialized supply chain processes.

They also provide the following capabilities:

- Unified management of highly specialized automation equipment from multiple vendors

- Management and track and trace of batches and serial numbers

- Support for quality assurance processes, including quarantining of tested products and documentation of test results

We can integrate our supply chain software solutions with cutting-edge voice-directed work solutions and specialized automation equipment, to increase overall efficiency.

With our extensive experience in the manufacturing sector, we can design holistic supply chain solutions that help optimize your logistics processes, so you can focus on your core operations.