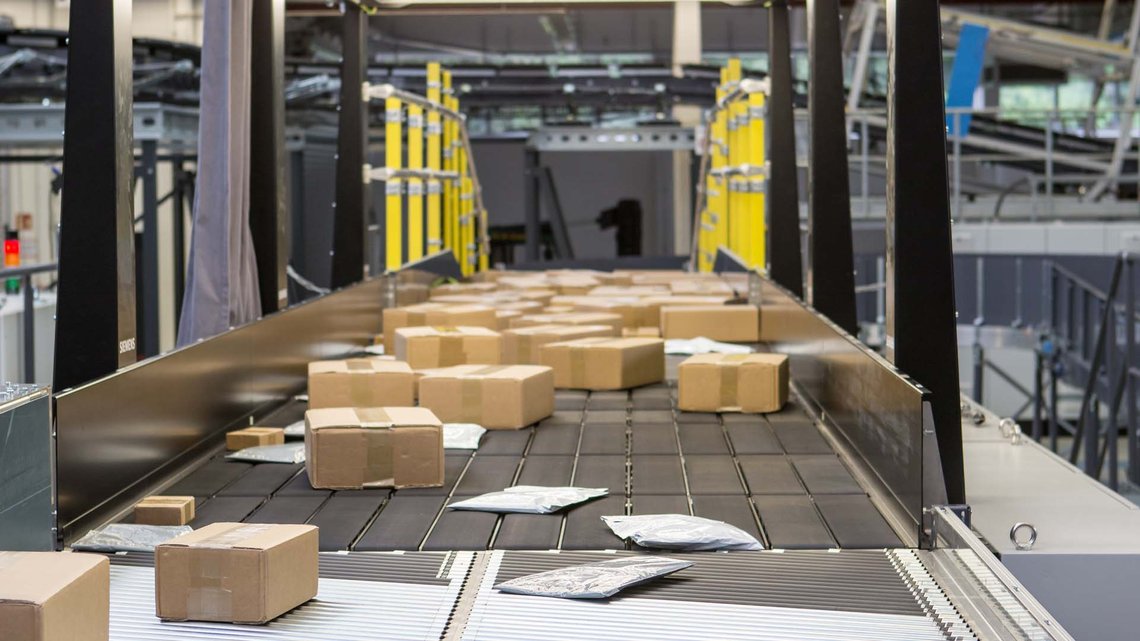

Visicon – throughput of up to 18,000 parcels per hour

This singulator generates a continuous stream of individual shipments arranged one after the other, with a pre-defined gap. Its variable transport speeds can handle throughputs of up to 18,000 consignments per hour.

An integral part of Visicon is its advanced AI-based vision system. It accurately detects and records the shape, size and relative position of each parcel and passes this information on to the control system. The system calculates singulation parameters – such as gapping and orientation – to align parcels precisely and fully automatically.

Adapted modules increase performance

Up- and downstream modules complement the product and optimize performance.

The upstream delayering line reorganizes consignments that lie on top of each other into a flow of uniformly distributed adjacent parcels.

The downstream alignment module lines the items up one after the other. A subsequent extraction module discharges non-machinable shipments. For defined gaps, an intelligently controlled module consisting of several conveyor belts is also available.

Visicon Compact – singulation on an extremely small footprint

Visicon Compact is a smaller version of the field-proven Visicon singulator. It boasts a very small footprint, which allows for more flexibility when it comes to integration into new layouts and existing systems. This intelligent, automatic solution reliably singulates up to 7,000 smaller items per hour on less than seven square meters.

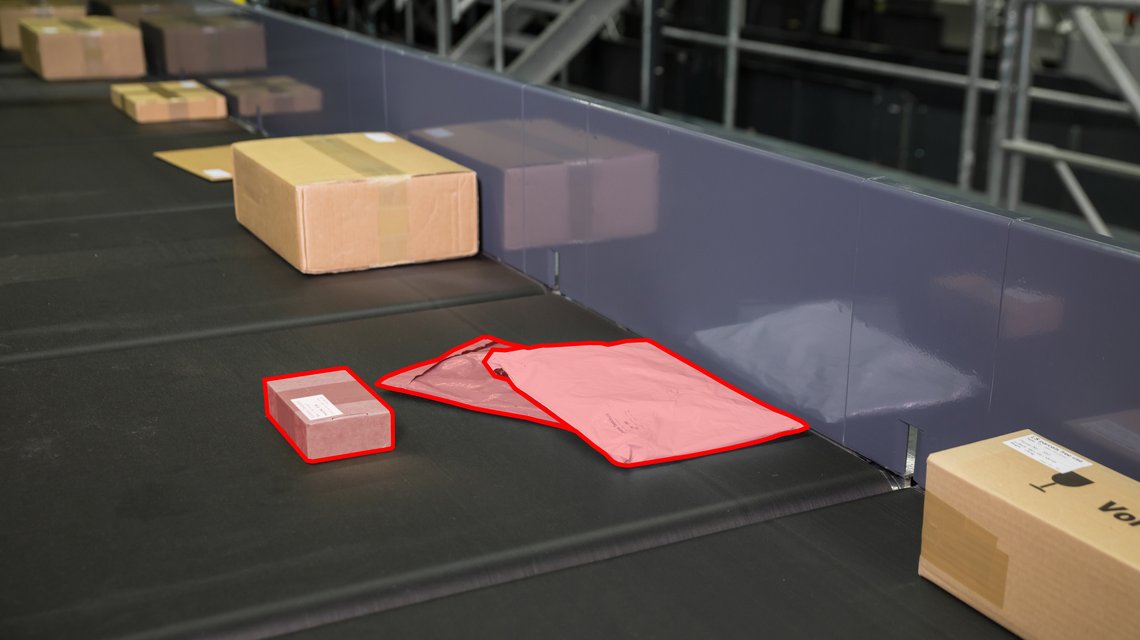

VarioDetect – reliable automatic exception detection

Accurate sorting requires items that are compatible with the systems’ processing spectrum. Incompatible shipments can result in missorts, cause jams or even damage equipment. Doubles – items that stick together – or two or more of them lying side-by-side, as well as misaligned or oversized parcels are examples that need to be identified and sorted out as quickly as possible.

This is where VarioDetect comes into play: It automatically identifies exceptions as they pass in an aligned stream. Intelligent algorithms analyze the data captured by 2D cameras and recognize whether there is an exception that needs to be removed. The corresponding information is then sent to the subsequent handling systems that automatically redirect those parcels.

The vision system is highly adaptable and can easily be trained to meet various customer needs. Its flexibility and adaptability make sure that high performance is maintained in spite of ever-changing packaging and formats.